Responding to challenges and creating the next systems and structures

Our main customers are industries that support social infrastructure, such as manufacturing (chemical, petroleum, and other types of plants) and power plants. We go beyond mere equipment sales to propose solutions for on-site issues, utilizing cutting-edge technologies in control, measurement, the Internet of Things (IoT), and digital transformation (DX). Our strength lies in our ability to work with in-house engineers to cover everything from design to installation, operation, and maintenance.

Solution proposals

Manufacturing sites and plants deal with a variety of issues, such as aging facilities, energy conservation, safety improvements, and work efficiency. We listen carefully to what people on the shop floor have to say, work to develop a thorough understanding of how processes and facilities work, and select and design the most appropriate systems and equipment, and then work everything together into proposals for specific solutions. On top of those proposals, we also provide consistent support for post-implementation operations and technical support to enable highly effective and sustainable improvements.

DX support

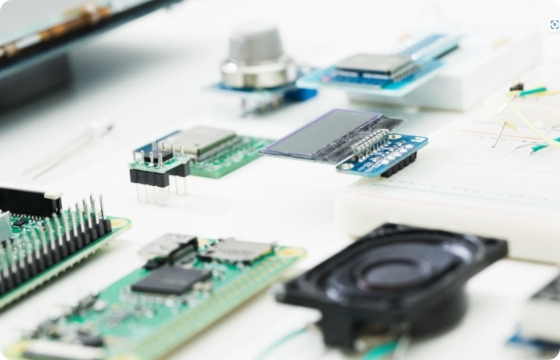

DX is an issue that companies in the manufacturing and energy industries need to address. In addition to proposals for using robotics for automation, labor and manpower savings, and accelerated inspection processes, we also contribute to smarter operations in a wide range of areas—from visualizing sites and performing remote monitoring via network cameras and drones to improving design accuracy through three-dimensional measurement (CAD modeling). We walk hand in hand with our clients as a "DX partner" with a perspective that extends all the way to operations and maintenance, including real-time, cloud-driven data integration and system construction with a view to future AI utilization.

Systems engineering

In the construction of systems for various plants and factories, technical areas like control, monitoring, production management, automatic inspections, remote control, and network construction interlock into a larger whole. Our system engineers, drawing on an understanding of how everything fits together, work to optimize the systems. When we engineer and implement systems, we keep the links with existing facilities and systems in mind and provide support to ensure stable operations.

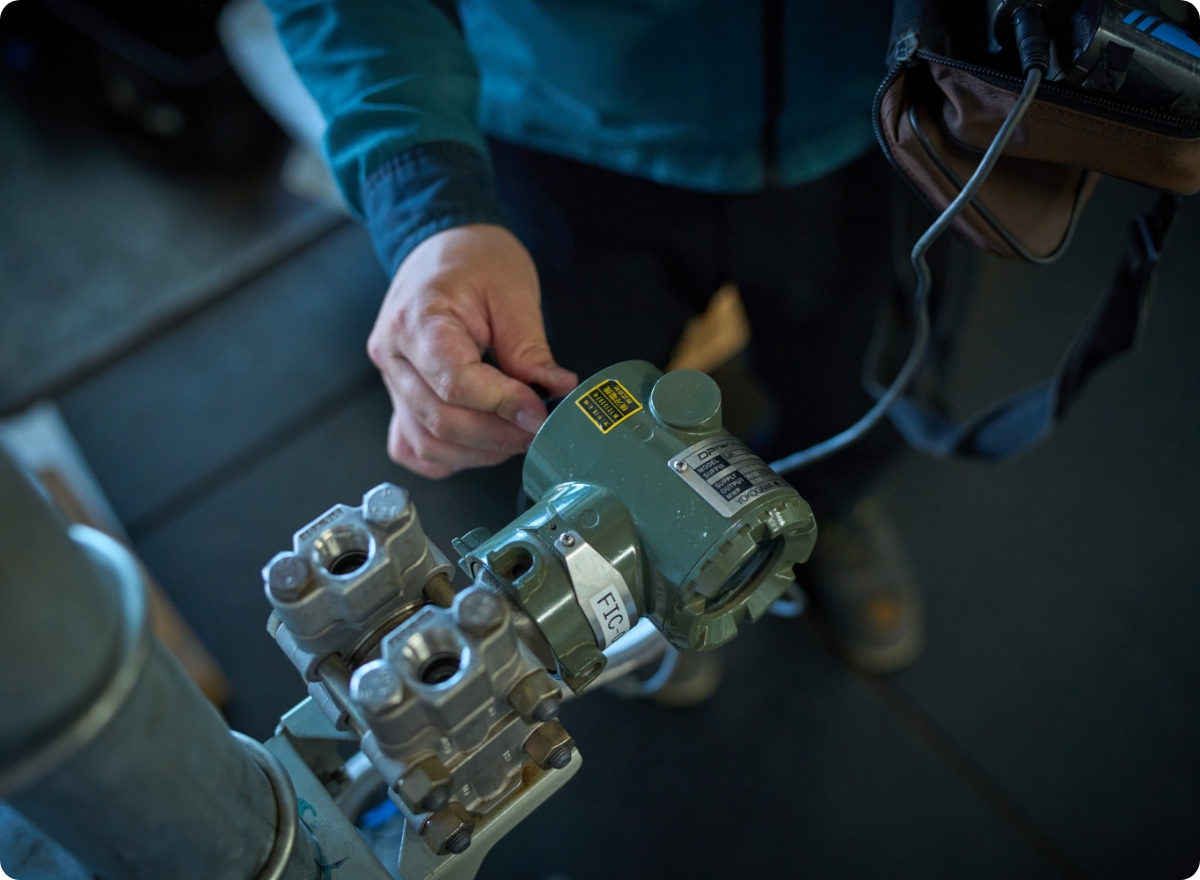

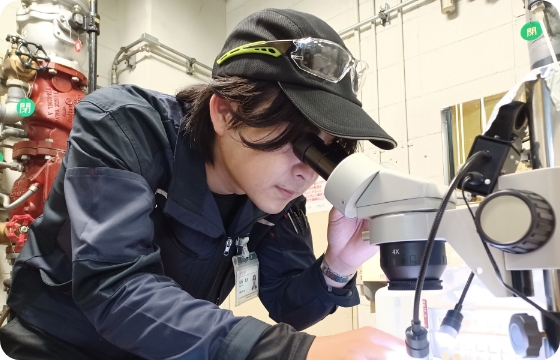

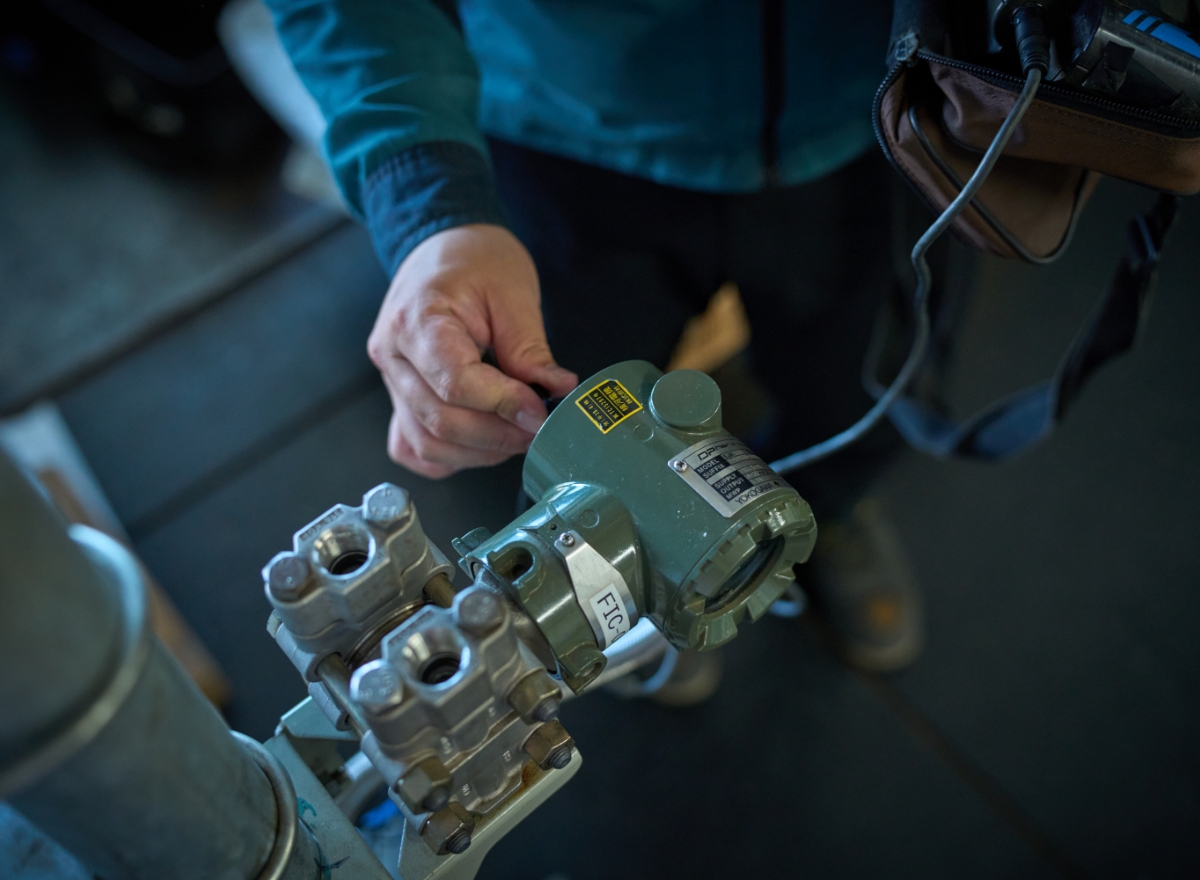

Service engineering

Our expert service engineers handle new plant construction, relocation, and startup support, along with integrated maintenance for existing facilities, repairs and updates of stand-alone equipment, and periodic inspections. Leveraging the strengths that our trading company features offer, we can immediately make arrangements to secure necessary parts in the event of a breakdown or other problem. That balance—technological prowess and procurement capabilities—enables us to deliver security and reliability to worksites where stable operations are a must.